1. What is atmospheric pressure plasma?

Plasma is the fourth form of matter. It is an aggregation state of matter composed of ions, electrons, neutral particles, and photons. It is usually defined as the number of positive and negative charged particles formed by the ionization of atoms in the gas. The conductor. The plasma can be generated and maintained under low pressure, medium pressure, and high pressure according to the environmental pressure in which the plasma is generated. Atmospheric cold plasma is a kind of plasma with a gas temperature close to room temperature and in a highly non-equilibrium state under atmospheric pressure, which is high pressure.

2. How does a plasma system work?

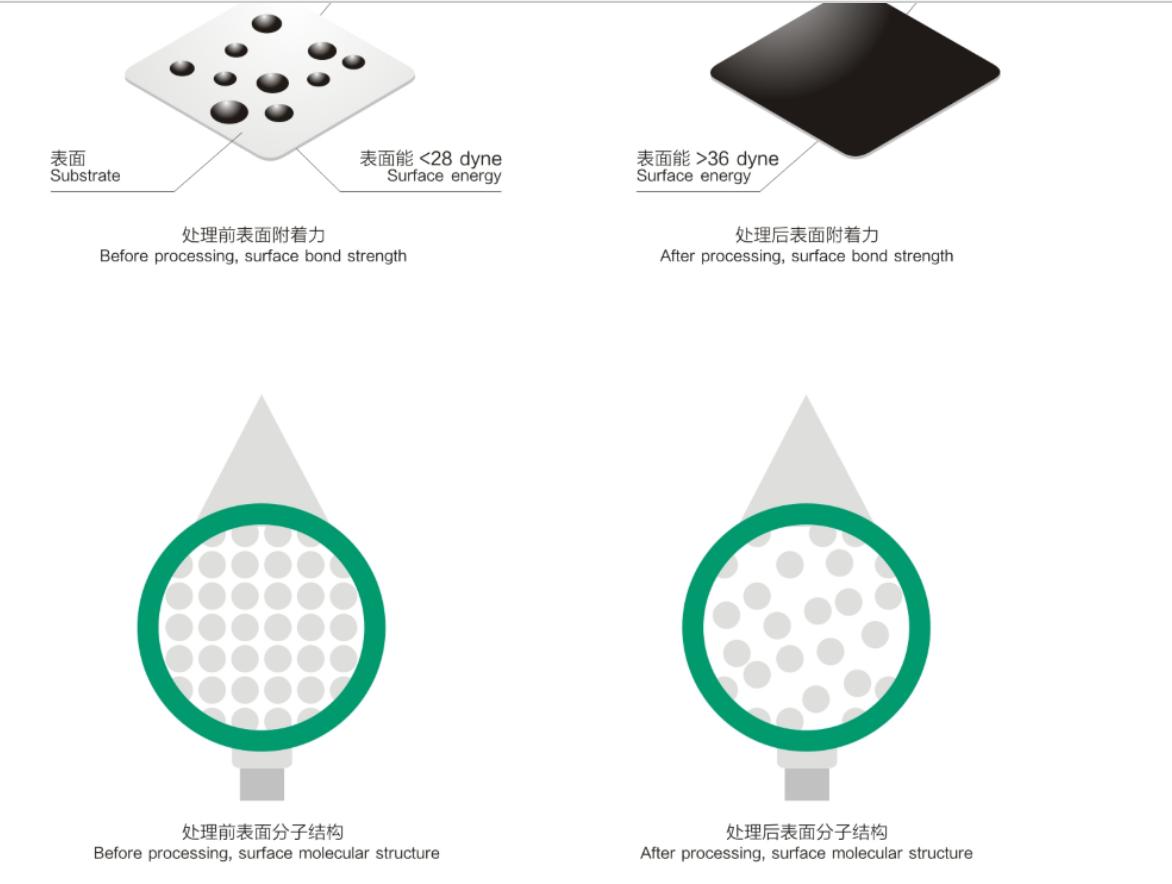

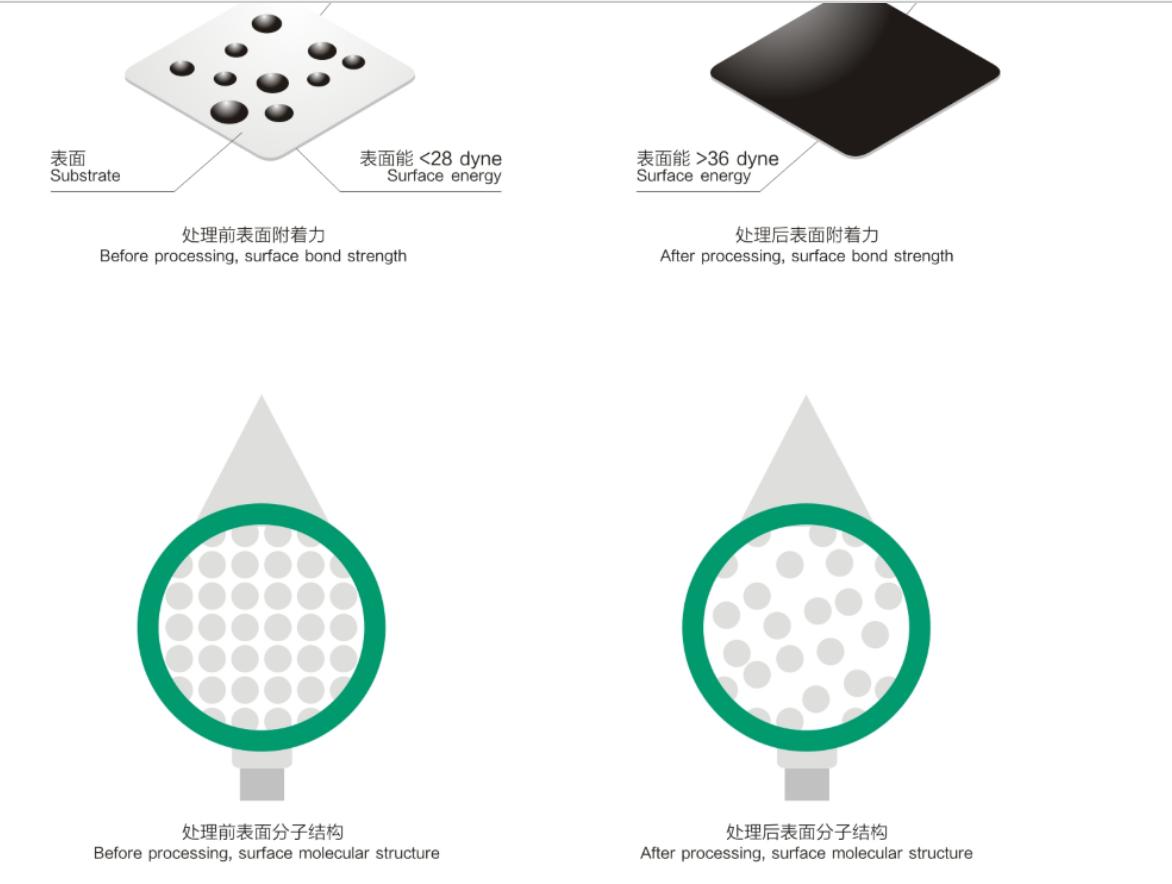

Generally speaking, cleaning/etching means the removal of interfering materials. Two examples of cleaning effects are the removal of oxides to improve the quality of brazing and the removal of organic contaminants on the surface of metals, ceramics, and plastics to improve adhesion. This is because glass, ceramics, and plastics are basically non-polar, so These materials undergo surface activation treatment before bonding, painting, and coating.

Plasma was initially applied to the cleaning of silicon wafers and mixed circuits to improve the reliability of bonding wires and soldering. Plasma surface cleaning equipment such as: removing organic pollution on the semiconductor surface to ensure good solder joint connection, wire bonding and metallization, as well as PCB, mixed circuit MCMS mixed circuit from the bonding surface left by the previous process Contamination, such as residual flux, excess resin, etc.

3. What is the working principle of the tape application system?

The work of the tape machine is divided into two parts, namely the printing and coating parts. In order to produce better products, the two parts have different work divisions.

Printing Place the roll to be printed on the unwinding roller and start the machine. The corresponding mechanism is driven to rotate by the transmission device, and the printing plate roller and the printing rubber roller are laminated to achieve gravure printing, and then through natural drying or heating and drying, the winding roller is wound to complete the printing function.

Coating Put the substrate to be coated on the unwinding roll, start the machine, and drive the corresponding mechanism to drive through the transmission device. The belt conveyor uses electricity, coal and gas three-in-one drying, electronic temperature control, stepless speed, automatic counting, automatic correction, gravure printing, advanced infrared heating, cooling and repressing and other high-tech. The production processes of collecting and unwinding, printing, coating, drying, hot air circulation, traction, slitting, and winding are completed in one machine.